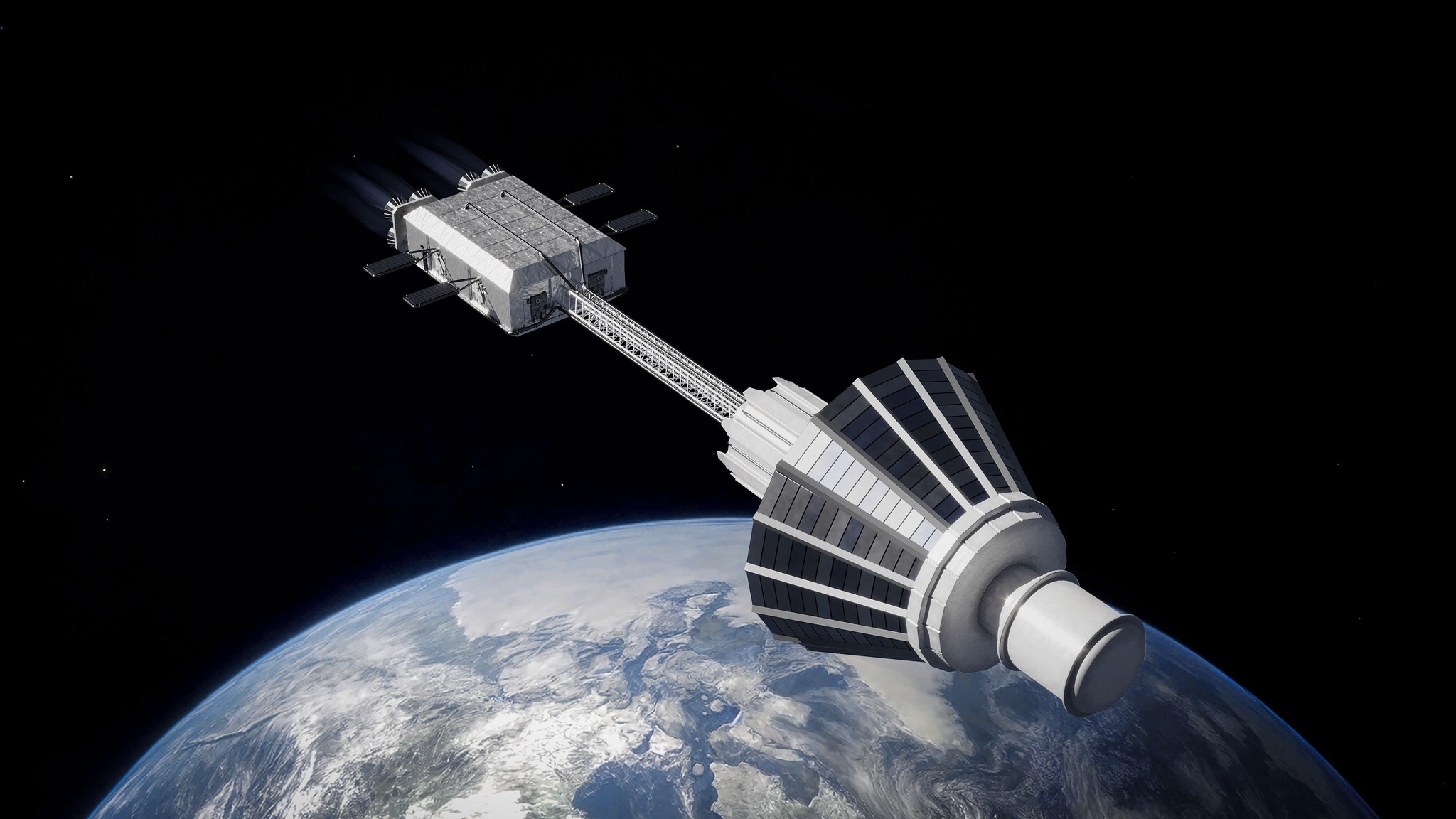

Abundant energy from Earth to the asteroid belt.

Abundant energy from Earth to the asteroid belt.

Abundant energy from Earth to the asteroid belt.

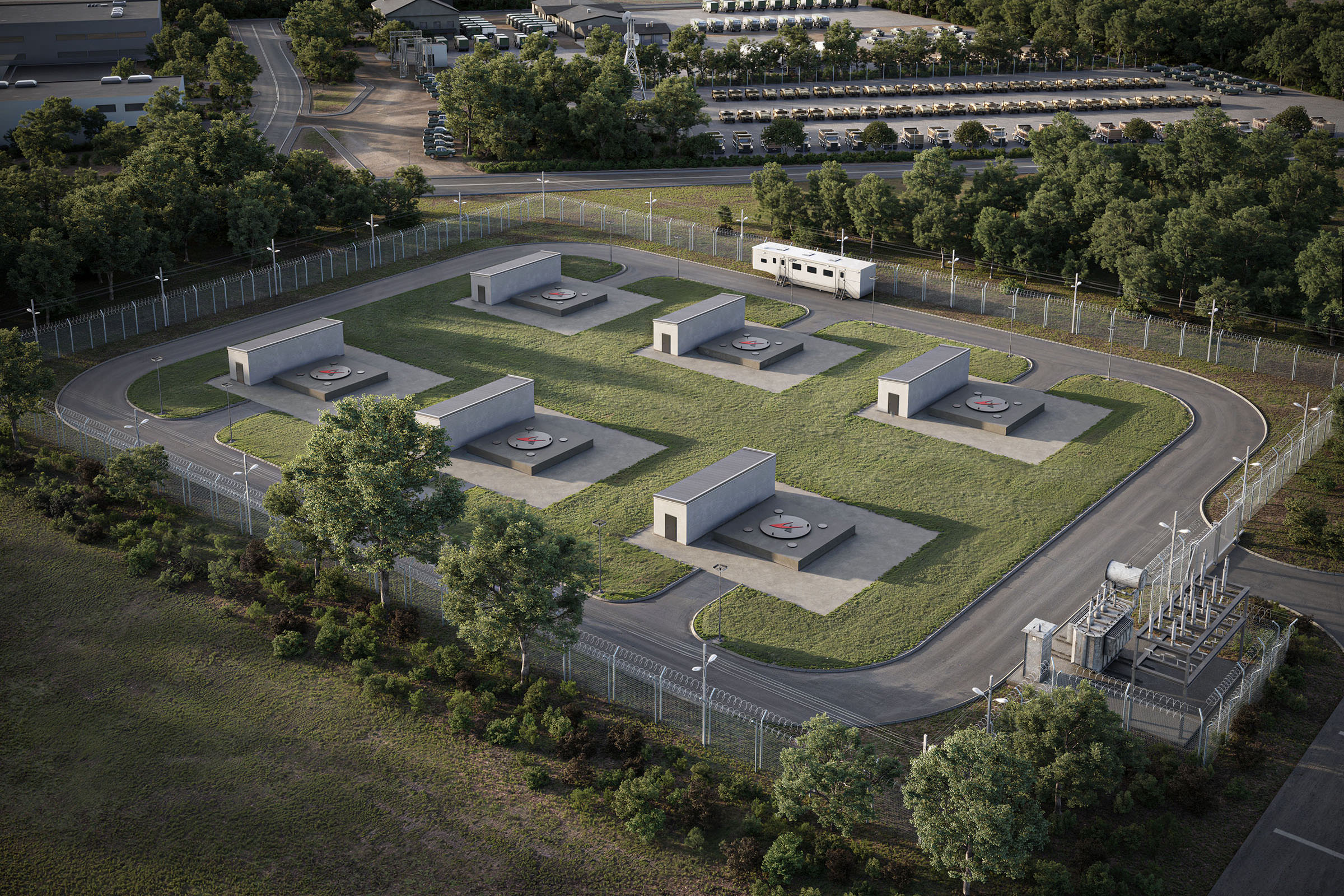

Fission microreactors to enable strategic energy for critical mission capabilities on Earth, in space, and underwater.

R1 Microreactor

Purpose-designed modular power for defense-critical assets

100kWe - 1MWe for 4-6 years

01

Integrated Shielding & Transport Cradle

Cradle simplifies deployment with minimal gear.

02

Reactivity Controls

Graphite and boron carbide control drums with independent actuator motors, inspired by historical space reactor designs.

03

Core

TRISO coated particle fuel in prismatic graphite core.

04

Sodium Heat Pipes

Sodium heat pipes enable redundant, high-temperature, entirely passive heat transfer.

05

Primary Heat Exchanger

Fin and tube heat exchanger.

06

Nitrogen Brayton Cycle

Simple recuperated N2 closed Brayton cycle enables efficient power conversion at < 300 psi. Low maintenance, low corrosion, leak resistant, and high reliability.

07

Power Management & Distribution

Electricity is conditioned through a power management and distribution node which can flexibly deliver power and connect to local microgrids.

ENGINEERING

Simple design optimized for reliability, uptime, and manufacturability

Simple design optimized for reliability, uptime, and manufacturability

Simple design optimized for reliability, uptime, and manufacturability

Capabilities

Vertically integrated supply chain

Vertically integrated supply chain

Vertically integrated supply chain

Special Purpose Reactors

We design and manufacture modular, transportable reactors for strategic energy applications on Earth and in space.

Special Purpose Reactors

We design and manufacture modular, transportable reactors for strategic energy applications on Earth and in space.

Special Purpose Reactors

We design and manufacture modular, transportable reactors for strategic energy applications on Earth and in space.

Heat Pipes & Thermal Management

Our expertise includes developing high-temperature heat pipes and radiators for compact thermal management.

Thermal Management

Our expertise includes developing high-temperature heat pipes and radiators for compact thermal management.

Thermal Management

Our expertise includes developing high-temperature heat pipes and radiators for compact thermal management.

Control Systems

Our team excels in design, build, and test of automated control systems, enabling hardware-in-the-loop digital twins.

Control Systems

Our team excels in design, build, and test of automated control systems, enabling hardware-in-the-loop digital twins.

Control Systems

Our team excels in design, build, and test of automated control systems, enabling hardware-in-the-loop digital twins.

Graphite Machining

We precision machine nuclear-grade graphite in house which accelerates our design iteration speed and feedback loop.

Graphite Machining

We precision machine nuclear-grade graphite in house which accelerates our design iteration speed and feedback loop.

Graphite Machining

We precision machine nuclear-grade graphite in house which accelerates our design iteration speed and feedback loop.

Roadmap to Full Power

Roadmap to Full Power

Roadmap to Full Power

2025

In 2025, we set the pace for advanced reactor development—completing our Conceptual Design Review (CDR) on an accelerated timeline and becoming the first company in the country to receive an approved Nuclear Safety Design Agreement (NSDA) for a reactor. We opened Antares Prime—145,000 sq-ft of vertically integrated R&D space—to accelerate in-house manufacturing and iteration, tested our first Electrically Heated Demonstration Unit (EDU), submitted our Preliminary Documented Safety Analysis (PDSA), prepared our reactor test site, and became the first U.S. microreactor to receive a HALEU allocation and begin fuel fabrication.

2026

In 2026, we will conduct our first reactor demonstration at Idaho National Laboratory under the Department of Energy’s Reactor Pilot Program—validating reactor physics, reactivity control behavior, and system-level safety performance in operation. In parallel, we will close the final reactor design and safety analysis and complete qualification of our heat pipes, heat exchanger, and power conversion system, setting the conditions for full-power operation in 2027.

2027

In 2027, we operate a full-power, electricity-producing advanced reactor on American soil. We will validate system performance and prepare for customer deployments beginning in 2028.

2025

In 2025, we set the pace for advanced reactor development—completing our Conceptual Design Review (CDR) on an accelerated timeline and becoming the first company in the country to receive an approved Nuclear Safety Design Agreement (NSDA) for a reactor. We opened Antares Prime—145,000 sq-ft of vertically integrated R&D space—to accelerate in-house manufacturing and iteration, tested our first Electrically Heated Demonstration Unit (EDU), submitted our Preliminary Documented Safety Analysis (PDSA), prepared our reactor test site, and became the first U.S. microreactor to receive a HALEU allocation and begin fuel fabrication.

2026

In 2026, we will conduct our first reactor demonstration at Idaho National Laboratory under the Department of Energy’s Reactor Pilot Program—validating reactor physics, reactivity control behavior, and system-level safety performance in operation. In parallel, we will close the final reactor design and safety analysis and complete qualification of our heat pipes, heat exchanger, and power conversion system, setting the conditions for full-power operation in 2027.

2027

In 2027, we operate a full-power, electricity-producing advanced reactor on American soil. We will validate system performance and prepare for customer deployments beginning in 2028.

2025

In 2025, we set the pace for advanced reactor development—completing our Conceptual Design Review (CDR) on an accelerated timeline and becoming the first company in the country to receive an approved Nuclear Safety Design Agreement (NSDA) for a reactor. We opened Antares Prime—145,000 sq-ft of vertically integrated R&D space—to accelerate in-house manufacturing and iteration, tested our first Electrically Heated Demonstration Unit (EDU), submitted our Preliminary Documented Safety Analysis (PDSA), prepared our reactor test site, and became the first U.S. microreactor to receive a HALEU allocation and begin fuel fabrication.

2026

In 2026, we will conduct our first reactor demonstration at Idaho National Laboratory under the Department of Energy’s Reactor Pilot Program—validating reactor physics, reactivity control behavior, and system-level safety performance in operation. In parallel, we will close the final reactor design and safety analysis and complete qualification of our heat pipes, heat exchanger, and power conversion system, setting the conditions for full-power operation in 2027.